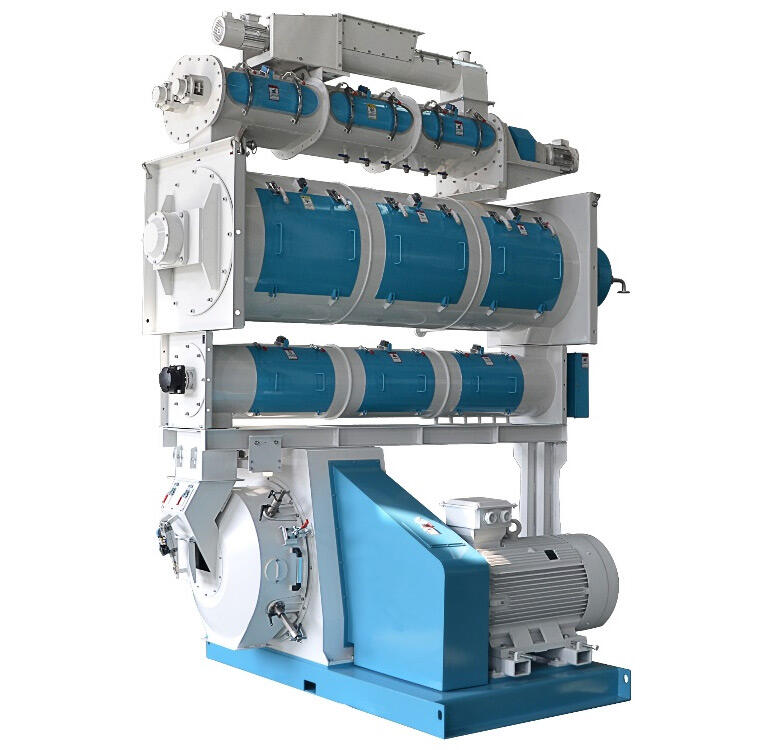

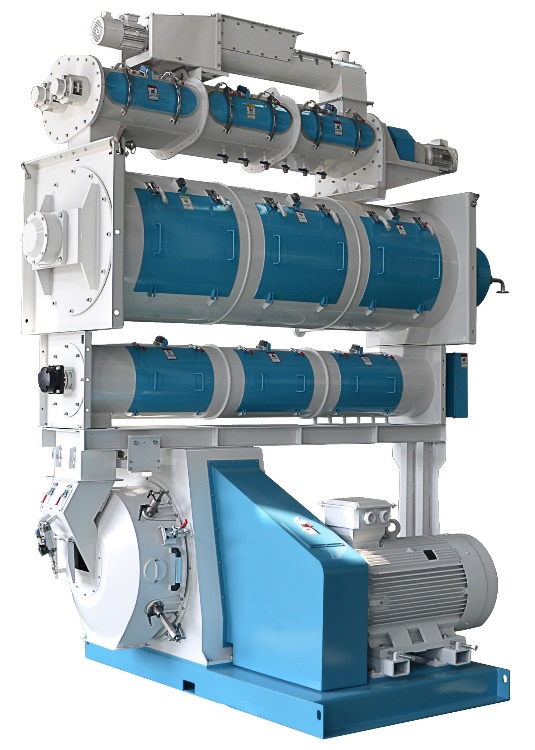

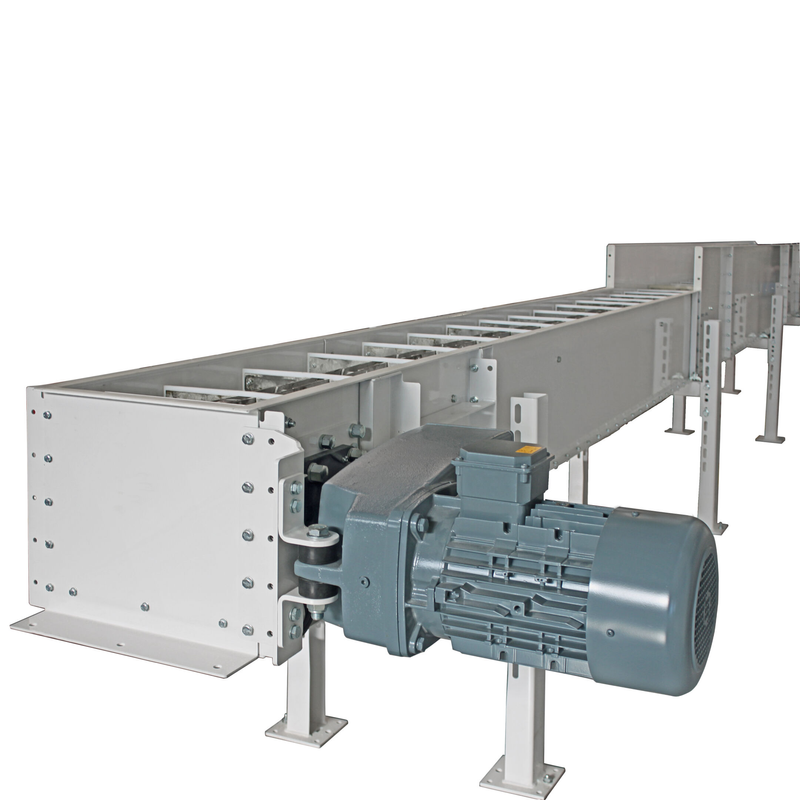

Pellet Mill

The pelletizer is a core equipment in feed processing, mainly used to press the mixed powdered feed into pellets to improve the palatability, nutritional utilization rate and storage and transportation efficiency of the feed.

MOQ: 1

- Overview

- Recommended Products

Product Overview

The pelletizer is a core equipment in feed processing, mainly used to press the mixed powdered feed into pellets to improve the palatability, nutritional utilization rate and storage and transportation efficiency of the feed.

Specifications and Parameters

| MODEL | MAIN POWER | DIA.OF RING DIE | PELLET SIZE | OUTPUT(T/H) |

| SZLH250 | 18.5KW | 250mm | 2-12mm | 1-2T/H |

| SZLH300 | 30KW | 200mm | 2-12mm | 2-4T/H |

| SZLH320 | 37KW | 320mm | 2-12mm | 3-5T/H |

| SZLH350 | 55KW | 350mm | 2-12mm | 4-8T/H |

| SZLH400 | 75KW | 400mm | 2-12mm | 7-15T/H |

| SZLH420 | 90KW | 420mm | 2-12mm | 9-18T/H |

| SZLH508 | 132KW | 508mm | 2-12mm | 13-20T/H |

| SZLH578 | 185KW | 572mm | 2-12mm | 17-22T/H |

| SZLH678 | 200KW | 673mm | 2-12mm | 20-30T/H |

| SZLH768 | 250KW | 673mm | 2-12mm | 25-40T/H |

Product Details Description

1) High-efficiency production: The automated control system enables continuous granulation, reducing labor costs.

2) Nutrient retention: The high-temperature and high-pressure granulation process gelatinizes starch and denatured proteins, enhancing the digestion and absorption rate.

3) Sterilization effect: Kills pathogenic microorganisms such as Salmonella to ensure feed safety.

4) Multi-functional adaptability: It can handle various raw materials such as corn, soybean meal, and straw, and can be used in conjunction with a modulator to add oil or molasses.