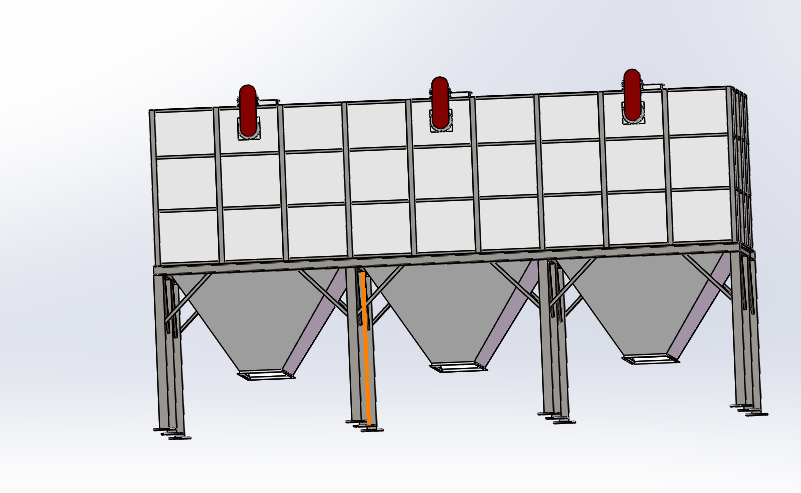

Shandong Juyongfeng Agricultural and Husbandry Machinery Co., Ltd., inspired by the principle “Grow together, undertake together, create together,” manufactures durable feeding bins that provide a secure and efficient solution for storing and dispensing feed materials. Based in Jinan, a key player in China’s flourishing feed industry, and with exports to over 60 countries, our feeding bins are constructed from high - quality materials such as galvanized steel or reinforced plastic, offering excellent resistance to corrosion, pests, and adverse environmental factors. These bins feature a large storage capacity and a sealed design, which effectively protects the feed from moisture, contamination, and spoilage, thereby maintaining its nutritional integrity. The feeding bins are equipped with user - friendly discharge mechanisms, including gravity gates and auger systems, that enable controlled and precise feed dispensing. Some models are integrated with built - in level sensors, providing real - time monitoring of feed levels, which helps farmers manage inventory effectively and avoid shortages. The modular design of our feeding bins allows for easy installation, expansion, and relocation, making them suitable for a wide range of agricultural applications, from small - scale family farms to large - commercial livestock operations. With our feeding bins, customers can ensure a reliable and consistent supply of high - quality feed, supporting the efficient and sustainable operation of their livestock and poultry production systems.