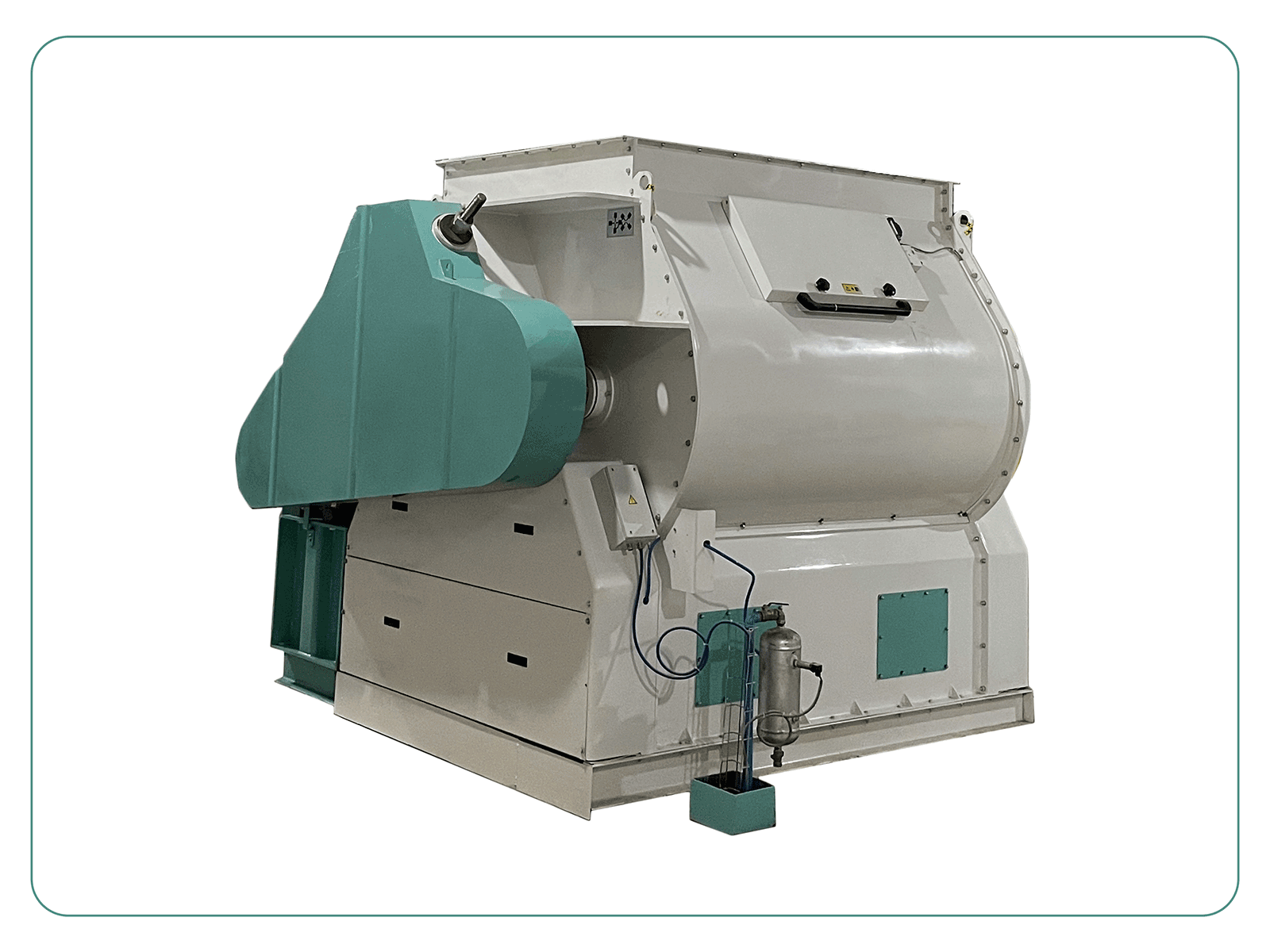

Double-shaft blade mixer

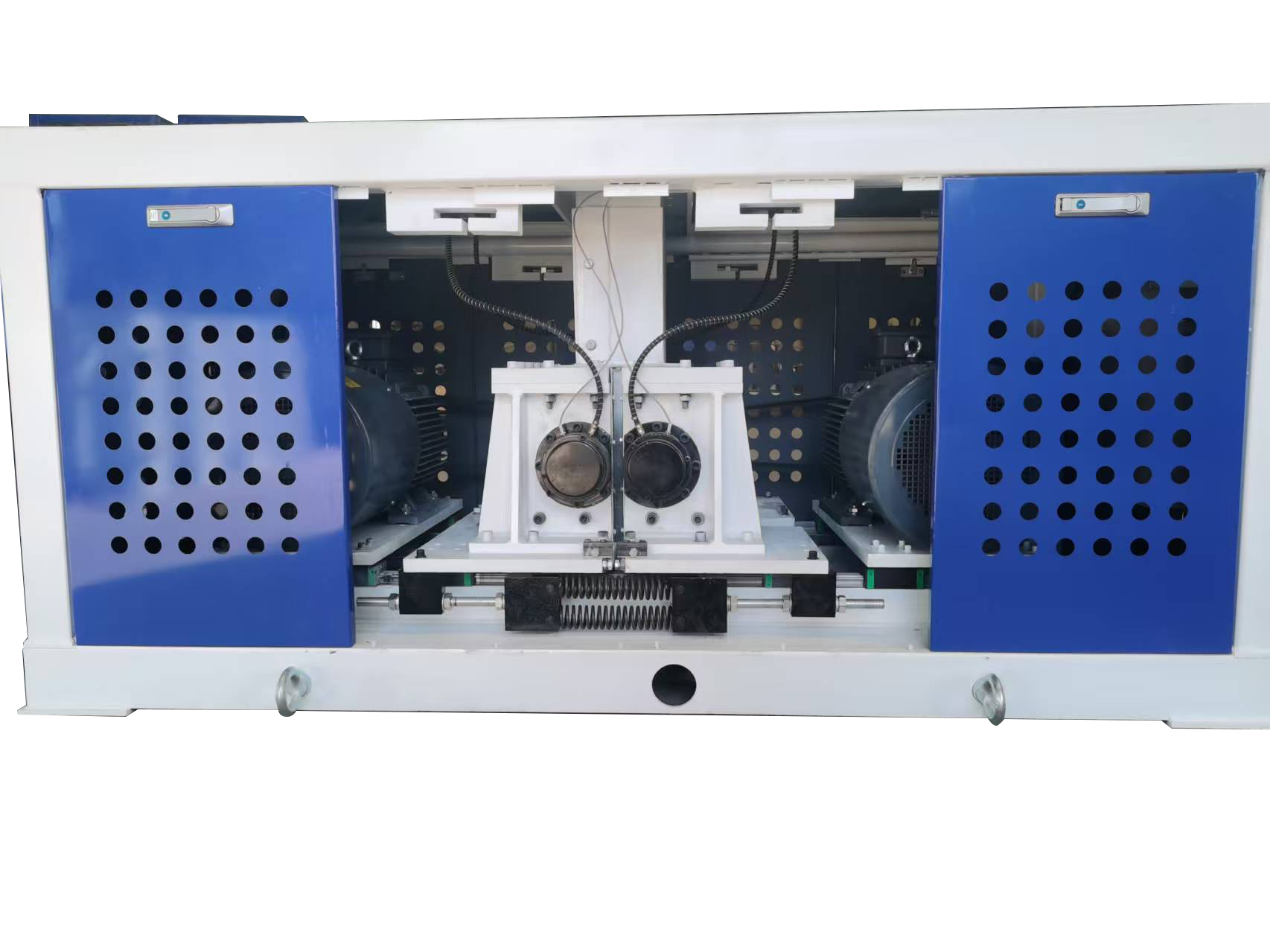

The motor drives two rotors with opposite rotation directions to rotate. Multiple specially angled paddles are welded on the rotors. The paddles carry the materials, and the materials form a continuous all-round circulation and reaction in the machine trough, interlaced and sheared with each other, thus achieving a fast, gentle and uniform mixing effect.

MOQ: 1

- Overview

- Recommended Products

Product Overview

The motor drives two rotors with opposite rotation directions to rotate. Multiple specially angled paddles are welded on the rotors. The paddles carry the materials, and the materials form a continuous all-round circulation and reaction in the machine trough, interlaced and sheared with each other, thus achieving a fast, gentle and uniform mixing effect.

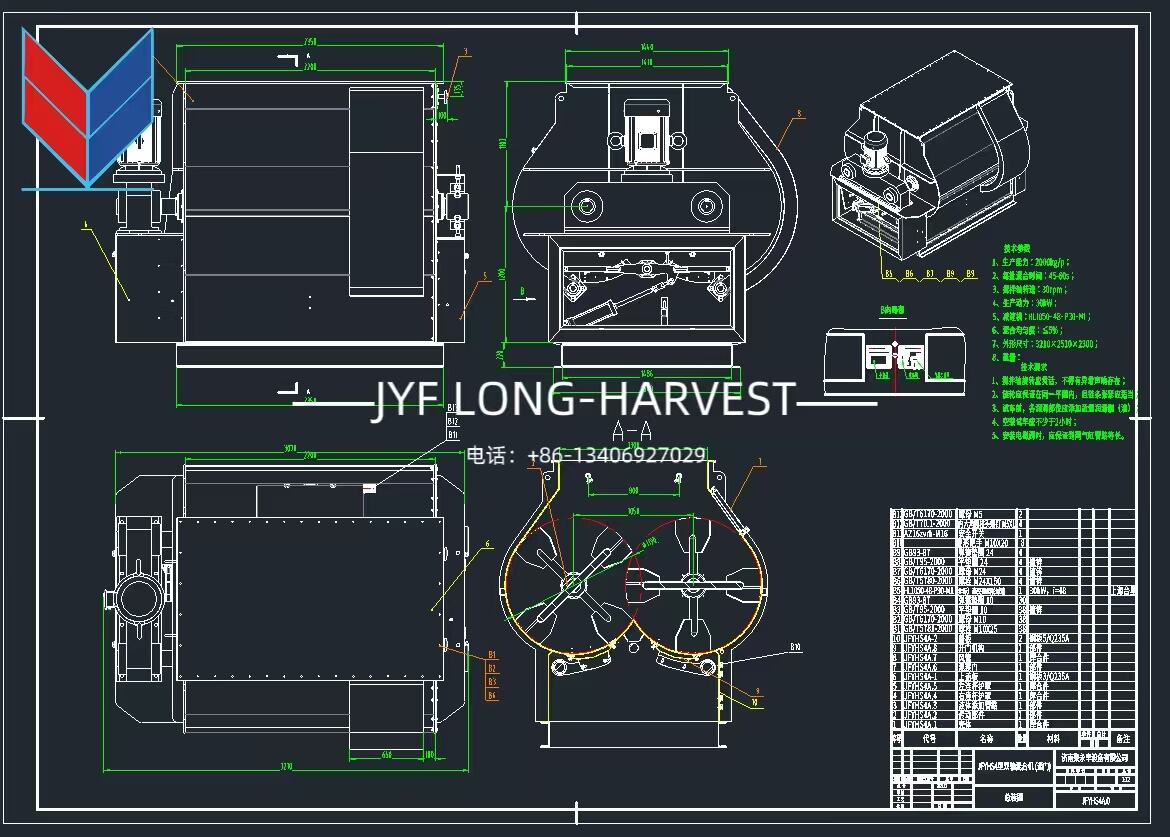

Specifications and Parameters

| MODEL | EFFECTIVE VOLUME(㎡) | MIXING AMOUNT(KG/P) | MIXING TIME(S) | UNIFORMITY OF MIXING(CV≤%) | POWER(KW) |

| JFYHS0.2 | 0.2 | 100 | 60-150 | 5 | 4 |

| JFYHS0.5 | 0.5 | 250 | 60-150 | 5 | 7.5 |

| JFYHS1.0 | 1.0 | 500 | 60-150 | 5 | 11 |

| JFYHS2.0 | 2.0 | 1000 | 60-150 | 5 | 18.5 |

| JFYHS4.0 | 4.0 | 2000 | 60-150 | 5 | 37 |

| JFYHS6.0 | 6.0 | 3000 | 60-150 | 5 | 55 |

Product Details Description

1) Short mixing cycle and high mixing uniformity: The material's mixing uniformity CV is ≤5% within 60 to 150 seconds, reducing the mixing time and enhancing production efficiency.

2) Large variable range of filling amount: The variable range of filling coefficient is 0.1-0.8, which is suitable for the mixing of materials of different densities, particle sizes, etc. in multiple industries.

3) No segregation during mixing: After the machine mixes evenly within 1 minute, the materials do not undergo classification, and there will be no segregation due to significant differences in physical properties such as density and particle size.

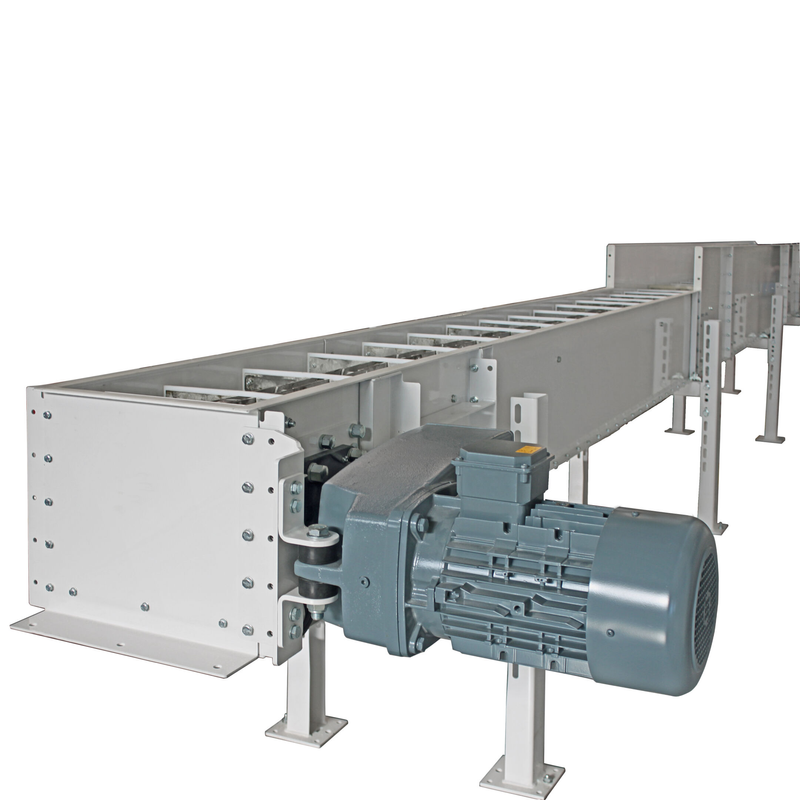

4) Fast discharge and low residue: The bottom adopts a pneumatic full-length double-door structure, which enables rapid discharge and minimal residue.