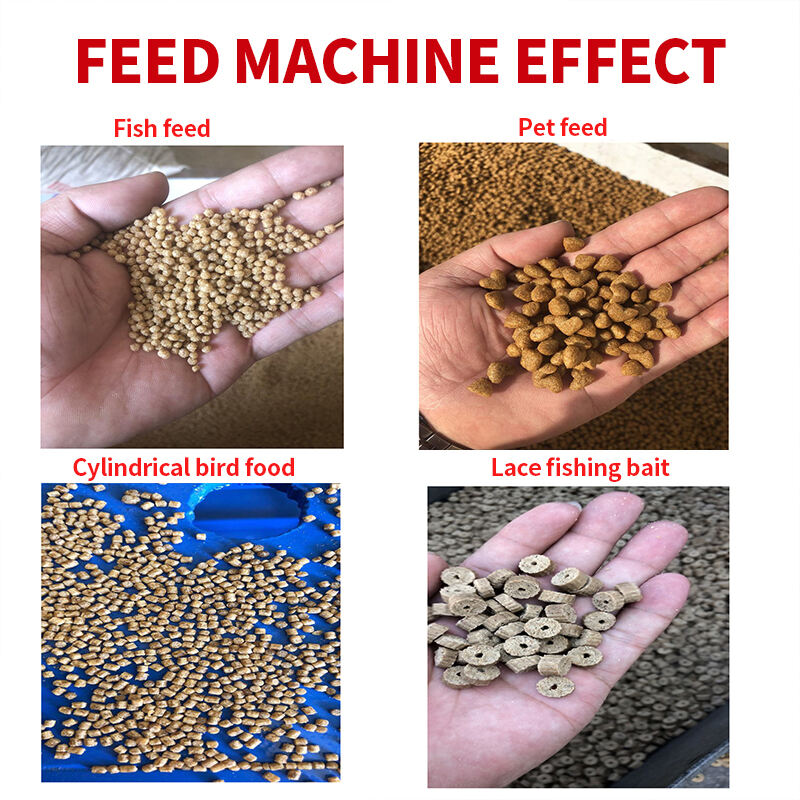

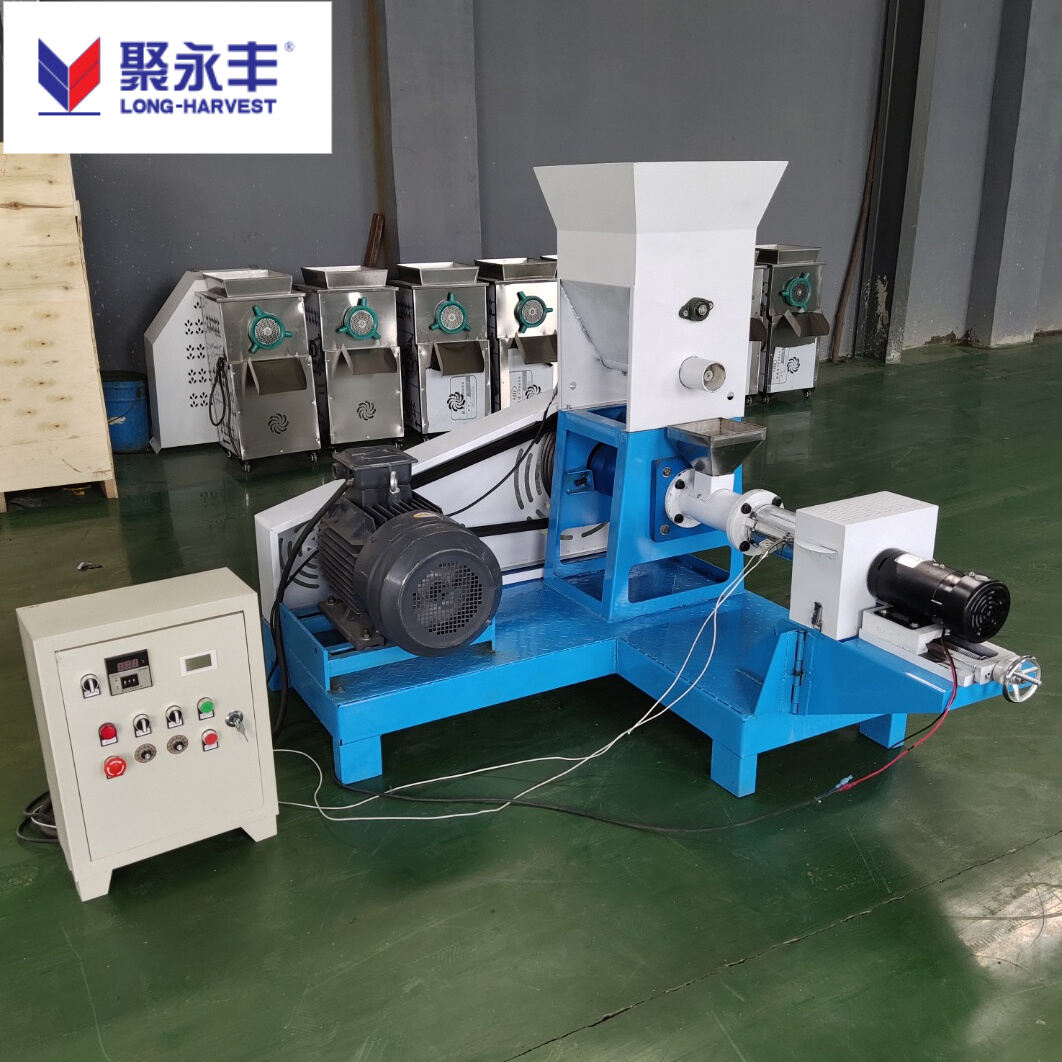

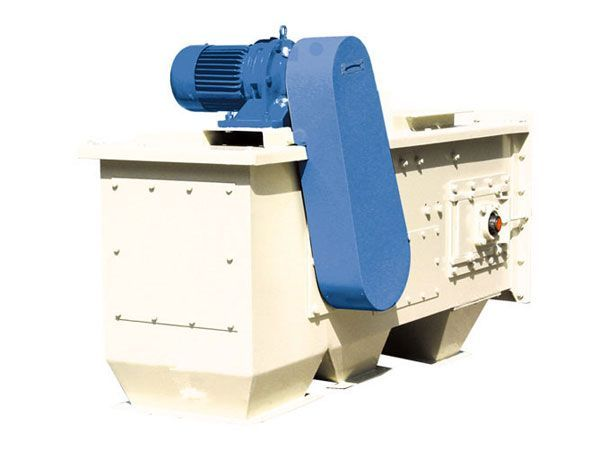

Puffing Pellet Mill/pellet extruder

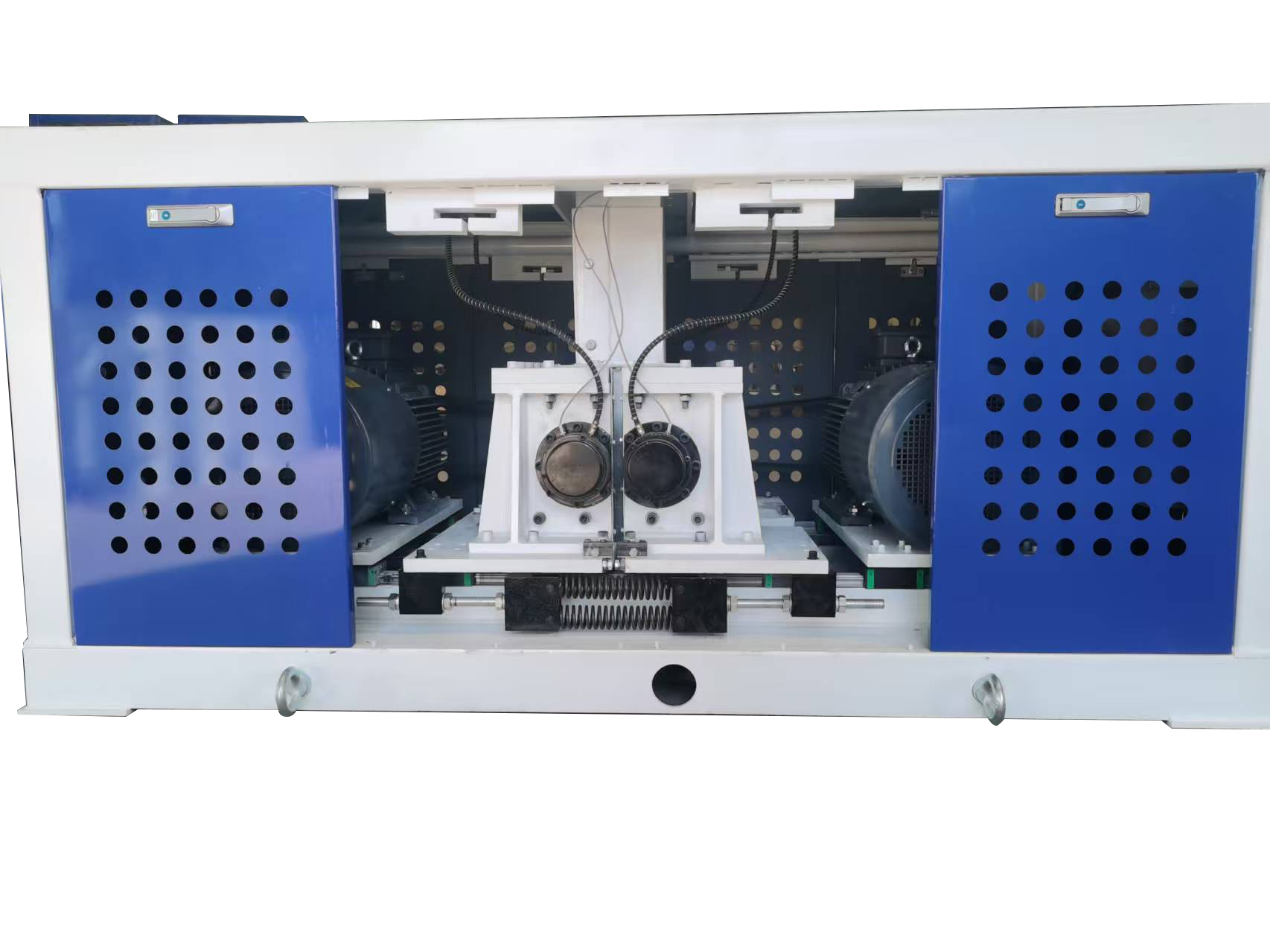

The feed extruder is a core equipment that uses high temperature, high pressure and high shear force to physically and chemically process feed raw materials, transforming them into specific shapes (such as pellets or strips) for extruded feed. It is widely used in the production of livestock, aquatic, and pet feed, and its core function is to improve feed quality and enhance breeding efficiency through the "extrusion" process.

MOQ: 1

- Overview

- Recommended Products

Product Overview

The feed extruder is a core equipment that uses high temperature, high pressure and high shear force to physically and chemically process feed raw materials, transforming them into specific shapes (such as pellets or strips) for extruded feed. It is widely used in the production of livestock, aquatic, and pet feed, and its core function is to improve feed quality and enhance breeding efficiency through the "extrusion" process.

Product Details Description

1) Improving the nutritional value and digestion absorption efficiency of feed:The gelatinization rate of starch has been significantly increased, with the gelatinization rate being able to rise from the traditional 40%-60% to over 80%. Protein denaturation is more easily absorbed, and the digestibility increases by 10% to 20%. The crude fiber softens and degrades, reducing the digestive burden on the animal's intestines and promoting intestinal peristalsis. It is particularly suitable for ruminant animals (cattle, sheep) and herbivorous aquatic animals (grass carp).

2) Strongly ensure the safety of feed and reduce the risk of diseases in breeding:Highly effective in killing harmful microorganisms. At temperatures ranging from 110 to 180°C and pressures of 2 to 10 MPa, it can quickly kill over 90% of harmful bacteria in the raw materials, such as Escherichia coli, Salmonella, and mold spores (for example, Salmonella is the main cause of diarrhea in piglets and chicks, and after being expanded, it can significantly reduce the incidence of such intestinal diseases); it can destroy anti-nutritional factors, expanding the range of raw materials while avoiding the risk of animal poisoning; it reduces the reliance on chemical additives and has strong sterilization and stable nutritional effects.

3) Enhance storage and usage convenience: Low moisture content, resistant to storage. The moisture content of the expanded material can be reduced to 10%-12% after post-treatment, which is below the critical value for mold growth; stable structure, resistant to crushing. The crushing rate during transportation and loading can be controlled below 3%; exclusive advantage for aquatic feed. The feed is not likely to disintegrate even after being soaked in water for more than 30 minutes.

4) Reduce production costs and enhance economic benefits: Expand the range of low-cost raw materials; Reduce waste at the production end; Simplify the production operation procedures;

5) Improve the palatability of feed, promoting animal feeding: Produce natural fragrance; Taste is more acceptable; Uniformity of ingredients is high;

6) Adapt to various scenarios, with strong application flexibility: wide range of product categories; customizable specifications; adjustable manufacturing processes;