Core Components and Technical Compatibility in Feed Processing Machine Lines

Key Components in a Feed Processing Machine System: From Grinder to Pellet Mill

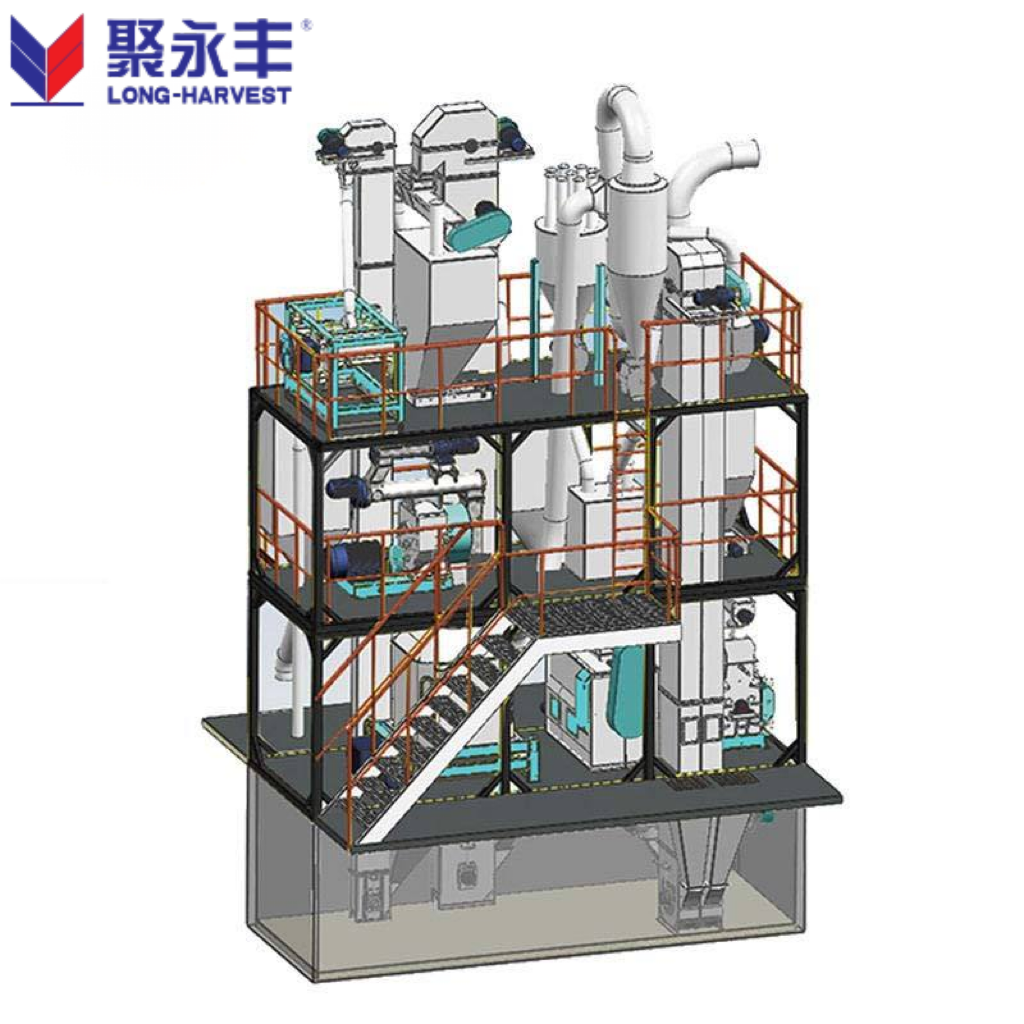

Putting together a full feed processing system means getting three main parts working together: the grinder, mixer, and pellet mill. Let's start with grinders. These machines take those big chunks of raw stuff like corn or soybeans and break them down into smaller pieces around half a millimeter to two millimeters in size. Why does this matter? Well, when particles are uniform, animals can actually digest their food better, and everything mixes properly without clumping up later on. Next comes the paddle mixer. This part of the process makes sure all those important additives get spread throughout the mix. We're talking about things like vitamins, enzymes, sometimes even flavorings depending on what kind of livestock we're feeding. And finally there's the pellet mill itself. This machine takes all that mixed material and squishes it into those neat little pellets we see at farms everywhere. The dies inside get pretty hot during this compression process, usually somewhere between sixty-five and eighty-five degrees Celsius. That heat helps turn starches into something more digestible for animals while making nutrients easier for them to absorb overall.

Technical Specifications That Affect Compatibility Across Feed Processing Machines

Getting equipment to work together properly depends mostly on matching their power capabilities and how they operate day to day. Take a 22 kilowatt grinder for example. When paired with a 37 kW pellet mill, this combination usually handles the workload pretty well without putting too much strain on the electricity supply. There are several key factors that need to line up though. The screw conveyor should run somewhere between 8 and 12 meters per minute. Mixers typically complete batches every 3 to 5 minutes. And for poultry feed production specifically, the die thickness needs to stay within 40 to 60 millimeters range. Getting these settings right helps avoid breakdowns from too much pressure or slowdowns in the production line.

Matching Machine Capacity (e.g., Mixer and Pellet Mill) for Optimal Throughput

| Component | Capacity Range | Ideal Pairing |

|---|---|---|

| Hammer Mill | 2—5 t/h | 3 t/h Batch Mixer |

| Pellet Mill | 3—8 t/h | 5 t/h Counterflow Cooler |

A 5 t/h pellet mill should be fed by a mixer with a slightly higher output of 5.2—5.5 t/h to compensate for 3—5% moisture loss during pelleting. Mismatched capacities can lead to 18—22% energy waste due to idle time or over-processing (FAO, 2022).

Standardized vs. Custom-Built Feed Processing Machine Configurations: Pros and Cons

Standardized lines offer faster deployment (4—6 weeks) and 15—20% cost savings, making them ideal for operations with conventional formulations. However, they lack flexibility for specialized feeds. Custom configurations support features like variable-speed conveyors or dual grinding stages, accommodating complex recipes—but require 8—12 weeks for calibration and increase initial investment by 30—40%.

Real-World Examples of Efficiently Matched Complete Feed Production Lines

A 2023 case study found that a mid-sized farm achieved 94% uptime by integrating a 7.5 kW grinder, a 10-ton mixer, and a 15 kW pellet mill. Synchronized automation minimized ingredient waste by 15%, underscoring how precision-matched components enhance efficiency and reliability.

Balancing Production Capacity Across Upstream and Downstream Units

Role of the Grinder or Crusher in Maintaining Feed Line Efficiency

Without question, the grinder sits at the heart of most feed processing systems, getting those raw ingredients ready for what comes next in the production line. Getting the settings right matters a lot - screen sizes usually range between 2 to 5 mm while rotor speeds typically fall somewhere around 1500 to 3000 RPM. When things aren't calibrated properly, we end up with big chunks that jam up pellet mill dies or dust-like fines that just overwhelm the mixers. That's why many newer facilities have started implementing load distribution strategies across several grinders. This approach really helps maintain system stability when dealing with large volumes of material through the plant.

Aligning Grinding Output with Mixing and Pelleting Rates to Prevent Bottlenecks

Keeping things flowing smoothly requires that a 10 ton per hour grinder can properly supply both the mixer with its 12 cubic meter capacity and the pellet mill which handles between 8 to 10 tons per hour. There are several important factors at play here. The material being processed has varying densities ranging from about 250 to 600 kilograms per cubic meter. Then there's the steam conditioning process which typically takes anywhere from half a minute up to nearly ninety seconds. And don't forget about those compression ratios in the pellet mill itself, usually sitting somewhere between 6 to 1 and 12 to 1. Modern systems that incorporate real time monitoring actually make adjustments on their own by changing conveyor belt speeds and opening gates as needed. These automated setups tend to produce around 22 percent more output compared to traditional manual operations where operators have to constantly watch gauges and make changes themselves.

Data Insight: 68% of Inefficiencies Stem from Mismatched Raw Material Processing Speeds (FAO, 2022)

According to FAO data, most inefficiencies occur at transfer points—grinders outpace mixers in 53% of cases, while pellet mills remain idle an average of 19 minutes per hour waiting for conditioned mash. Following ANSI/ASAE EP433 guidelines, maintaining a 10—15% buffer between sequential machines accommodates natural variations and prevents bottlenecks.

Integrated Layout and Conveying Systems for Seamless Material Flow

Optimizing Feed Production Line Layout: Minimizing Distance and Maximizing Automation

Efficient layouts minimize transit distances between processing units while maximizing automation. Research shows streamlined equipment sequencing can reduce material handling costs by 22%. U-shaped designs incorporating robotic arms and automated guided vehicles (AGVs) now manage 65% of transfers in advanced facilities, significantly reducing manual errors and cycle times.

Hopper and Conveyor Integration: Ensuring Smooth Transfers Between Processing Stages

Hoppers equipped with load-sensitive discharge mechanisms deliver materials at rates synchronized with downstream demand. Volumetric screw conveyors, for example, maintain ±3% accuracy relative to pellet mill input, preventing accumulation before cooling. This integration reduces raw material waste by 9% in high-volume lines exceeding 10 tons/hour.

Types of Conveyors Used in Feed Processing and Their Synchronization Role

- Belt conveyors: Move bulk grains horizontally at rates up to 150 TPH

- Screw conveyors: Elevate powdered additives vertically with 95% retention

- Pneumatic conveyors: Transport heat-sensitive premixes at 20 m/s without degrading nutrients

PLC systems synchronize conveyor speeds with mixer cycles via RFID-tagged batches, enabling 89% first-pass efficiency across fully integrated feed lines.

Automation and Control Solutions for Coordinated Feed Processing Machine Operation

PLC-Based Control Systems for Synchronizing Mixer, Pellet Mill, and Cooler Operations

Programmable Logic Controllers (PLCs) coordinate critical equipment by enforcing precise timing and speed control. These systems maintain ±0.5% synchronization between mixers, pellet mills, and coolers, eliminating pileups in transition zones. Independent testing shows PLC-managed lines achieve 92% operational efficiency, compared to 78% in manually controlled setups.

Industrial Automation for Real-Time Monitoring of Feed Processing Machine Performance

IoT sensors monitor motor loads, die temperatures, and moisture levels every two seconds, streaming data to centralized dashboards. This enables immediate intervention when anomalies—such as rising mixer torque—are detected, preserving pellet quality and preventing unplanned stops.

Implementing SCADA Systems to Enhance Equipment Integration in Existing Lines

SCADA systems unify legacy and modern equipment by standardizing communication protocols across brands. A 2023 integration project demonstrated a 32% reduction in unplanned downtime through predictive alerts and automatic adjustments in cooling parameters. These platforms also allow remote recipe updates without hardware modifications, improving responsiveness in multi-product facilities.

Emerging Trend: AI-Driven Predictive Maintenance in Automated Feed Production

Machine learning models analyze vibration patterns and motor current trends to predict bearing failures 14—21 days in advance. Early adopters report a 40% drop in emergency shutdowns by scheduling replacements during planned maintenance, minimizing disruption and extending equipment life.

FAQs

What are the main components of a feed processing machine system?

The main components of a feed processing machine system include a grinder, mixer, and pellet mill, each playing a crucial role in breaking down raw materials, mixing additives, and forming pellets.

Why is matching machine capacity important?

Matching machine capacity is important to prevent energy waste and ensure efficient production. If capacities are mismatched, it can lead to idle time or over-processing.

How do standardized and custom-built configurations differ?

Standardized configurations are quicker and cheaper to deploy but less flexible, while custom-built configurations offer more features and accommodate complex requirements but have higher initial costs and longer setup times.

How do PLC-based control systems improve feed processing?

PLC-based control systems synchronize operations between machines, increase efficiency, and prevent pileups, contributing to higher operational efficiency.

What emerging trends are there in feed processing automation?

AI-driven predictive maintenance is an emerging trend, using machine learning to predict equipment failures and reduce downtime.

Table of Contents

-

Core Components and Technical Compatibility in Feed Processing Machine Lines

- Key Components in a Feed Processing Machine System: From Grinder to Pellet Mill

- Technical Specifications That Affect Compatibility Across Feed Processing Machines

- Matching Machine Capacity (e.g., Mixer and Pellet Mill) for Optimal Throughput

- Standardized vs. Custom-Built Feed Processing Machine Configurations: Pros and Cons

- Real-World Examples of Efficiently Matched Complete Feed Production Lines

- Balancing Production Capacity Across Upstream and Downstream Units

- Integrated Layout and Conveying Systems for Seamless Material Flow

-

Automation and Control Solutions for Coordinated Feed Processing Machine Operation

- PLC-Based Control Systems for Synchronizing Mixer, Pellet Mill, and Cooler Operations

- Industrial Automation for Real-Time Monitoring of Feed Processing Machine Performance

- Implementing SCADA Systems to Enhance Equipment Integration in Existing Lines

- Emerging Trend: AI-Driven Predictive Maintenance in Automated Feed Production

- FAQs