High Throughput and Continuous Material Flow

Throughput Capacity of Bucket Elevators Maximizes Feed Line Efficiency

Modern bucket elevators achieve throughput capacities exceeding 300 tons/hour in feed processing, enabling 20–25% faster production cycles compared to alternative conveying methods, according to a 2023 material handling study. This efficiency stems from synchronized buckets operating at 1.5–4 m/s with individual capacities ranging from 0.5 to 1,500 liters.

Continuous Bucket Elevator Applications Ensure Steady Material Flow

Centrifugal discharge bucket elevators provide uninterrupted flow with ±2% consistency, essential for downstream processes like pelleting and mixing. Data from 42 feed mills show this continuous operation reduces downtime by 60% while maintaining over 99% operational availability.

Material Handling Capabilities Support High-Volume Feed Operations

| Capacity Tier | Typical Application | Energy Use (kWh/ton) |

|---|---|---|

| <100 tph | Specialty feeds | 0.8–1.2 |

| 100–300 tph | Commercial poultry | 0.6–0.9 |

| >300 tph | Bulk commodity | 0.4–0.7 |

Case Study: Throughput Improvement in a Poultry Feed Plant Using Bucket Elevators

A Midwest feed producer increased annual output by 37%—from 82,000 to 112,400 tons—after replacing pneumatic conveyors with dual 250 tph bucket elevators. The $1.2 million retrofit achieved a 14-month ROI through 30% lower energy costs and 22% faster line speeds.

Trend Toward Larger-Capacity Bucket Elevators in Modern Feed Mills

Recent surveys indicate 68% of new feed mill projects now specify bucket elevators with €400 tph capacity, up from 42% in 2018. This shift aligns with USDA data showing a 31% average increase in feed production per facility since 2020.

Energy Efficiency Compared to Pneumatic Conveying Systems

Energy Efficiency Compared to Pneumatic Systems Reduces Operational Costs

When it comes to moving materials vertically, bucket elevators actually use about 30 to 50 percent less power compared to those old fashioned pneumatic systems. That means real money saved on electricity bills over time. Pneumatic systems typically guzzle around 2.1 to 3.4 kilowatt hours per ton because they need all that compressed air, whereas bucket elevators are much more efficient at just 0.8 to 1.2 kWh per ton according to some industry reports I've seen. Take a standard feed mill processing 50 tons every hour as an example. The difference between these two methods adds up fast, resulting in annual savings that can go well beyond fifty eight thousand dollars each year for operations running consistently throughout the season.

Lower Power Consumption Due to Mechanical Vertical Conveying in Bucket Elevators

Bucket elevators are designed mechanically to prevent air leaks and those pesky compressor problems that plague pneumatic systems. When discharging materials, these systems actually use gravity to their advantage, which cuts down on how hard the motor has to work. Tests from last year showed something pretty impressive too. The energy transfer efficiency hits around 82%, compared to just 54% for pneumatic systems when moving corn meal up to those tall 25 meter silos. Makes sense why so many operations have switched over in recent years.

Industry Paradox: When Pneumatic Systems Are Chosen Despite Higher Energy Use

Even though they cost about 60 percent more in energy expenses, around a quarter of feed mills still went with pneumatic conveyors last year. Most folks do this because they're stuck on old ideas about controlling dust and having flexible operations. This thinking really sticks around in places that deal with very fine powders below 100 microns. Operators there think pneumatic systems work better for these materials, but many don't realize that newer bucket elevators now come with sealed chains and accurate discharge features that actually match what pneumatic systems can do. The gap between these options has pretty much disappeared thanks to recent improvements in elevator technology.

Gentle Handling to Preserve Feed Quality

Gentle Handling of Fragile Materials Preserves Pellet Integrity

Bucket elevators help keep pellets intact because they actually hold onto the material as it moves vertically, which means no those harsh impacts we see in pneumatic systems. For stuff like soybean meal or pellets packed with extra vitamins, even small cracks matter a lot. When more than 2% of the pellets break apart, the whole nutritional profile starts to suffer according to Feed Tech Journal last year. Get those bucket elevators set up right and collision problems drop between 40 to 60 percent over what happens when just letting stuff fall freely into bins. Makes sense why feed manufacturers care so much about getting this part of their operation dialed in.

Bucket Styles and Discharge Methods Influence Material Degradation

Centrifugal discharge systems minimize abrasion using controlled rotational force, while continuous designs ensure steady flow with minimal spillage. Polyethylene buckets with rounded edges—now widely adopted by leading manufacturers—reduce particulate scraping by 30% compared to traditional metal buckets.

Data Point: 30% Reduction in Fines Generation With Centrifugal Discharge Bucket Elevators

A 2023 study across 14 feed mills found centrifugal discharge elevators generated only 1.2% fines, compared to 1.7% in continuous models—a 30% improvement in product preservation. Their enclosed design also reduced cross-contamination risks by 22% versus open conveyors.

Controversy Analysis: Trade-offs Between Speed and Material Damage in Bucket Elevator Operation

When belt speeds go up between 1.5 and 2.5 meters per second, production definitely goes up but so does the force particles hit each other with something like 18% more every time speed increases by half a meter per second. Many plant managers will tolerate an extra 0.5 to 1 percent of fine material just to get that extra output through the system. Others though stick rigidly to quality standards and won't let belts run faster than 1.2 m/s no matter what. Finding the sweet spot really comes down to how delicate the ingredients are and exactly what kind of finished product specifications need to be met. Some facilities have learned this the hard way after breaking valuable materials during processing runs.

Space-Saving Vertical Conveying for Compact Mill Layouts

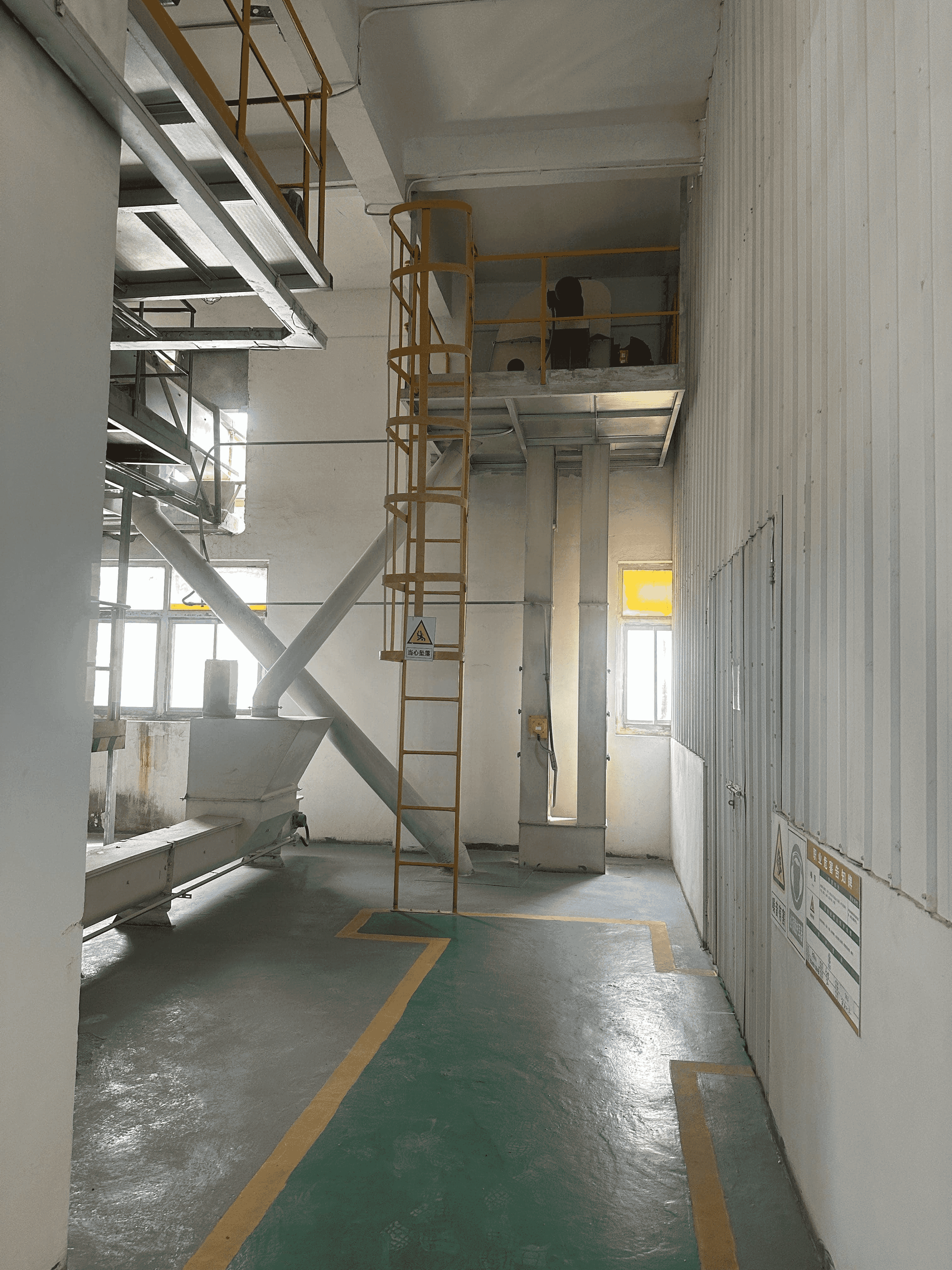

Vertical Conveying in Bucket Elevators Optimizes Space Utilization

Vertical movement of materials through bucket elevators can cut down on floor space requirements by around 40 to 60 percent when compared with traditional horizontal belt systems, something industry experts have been noting lately. These modern installations can actually climb over 30 meters high while using under 25 kilowatts of power, making them especially valuable for manufacturers located in cities where property prices run about 28% above what they do in countryside locations based on last year's agricultural facility survey data. What makes these systems so useful isn't just their compact design but also how they keep everything contained during transport. The sealing system stops material from spilling out, which means operators can install these machines right next to other equipment without worrying about messes getting in between different processing steps.

Material Suitability for Bucket Elevators in Multi-Level Processing Plants

Vertical bucket elevators reliably transport diverse feed ingredients—from fragile pellets to abrasive minerals—across multiple levels without sacrificing flow. Operational data shows 98% material retention in four-story facilities using centrifugal discharge models, far surpassing the 84% retention rate of pneumatic systems. This vertical integration allows mills to:

- Position raw intake at ground level

- Locate grinding and mixing on mezzanines

- Store finished products in overhead silos

This layout reduces inter-process conveyor lengths by 70% compared to single-level designs, while modular construction supports future capacity expansion without structural changes.

Low Dust and Fines Generation Improve Safety and Product Quality

Dust and fines generation is minimized in enclosed bucket elevator systems

Enclosed bucket elevators reduce particulate emissions by 40–60% compared to open conveying systems. The sealed design prevents leakage and channels residual dust to integrated filtration points, preserving ingredient consistency and reducing contamination risks—key for maintaining nutritional accuracy and avoiding costly recalls.

Improved air quality and reduced explosion risks in feed processing

Today's bucket elevators come equipped with NFPA compliant features that address combustible dust risks, including proper explosion venting systems and conductive parts throughout the design. These safety measures matter a lot for operations dealing with materials that catch fire easily, think fat-coated pellets or vitamin powders. When particle size drops below 500 microns, things get really dangerous in terms of potential explosions. Another benefit worth mentioning is how the vertical setup keeps different areas separated, which helps prevent contamination issues while also shielding staff members from breathing in those tiny airborne particles that can cause health problems over time.

FAQ

What is the throughput capacity of modern bucket elevators?

Modern bucket elevators can achieve throughput capacities exceeding 300 tons per hour, facilitating faster production cycles compared to alternative conveying methods.

How do bucket elevators contribute to energy efficiency in feed processing?

Bucket elevators use 30 to 50 percent less power compared to pneumatic systems, resulting in significant savings on electricity bills over time due to their mechanical vertical conveying and gravity-based discharge system.

What precautions are taken to prevent material damage in bucket elevators?

Bucket elevators minimize abrasive contact using centrifugal discharge systems and rounded-edge polyethylene buckets to ensure gentle handling of fragile materials.

Why do some facilities still choose pneumatic systems despite their higher energy use?

Around a quarter of feed mills opt for pneumatic systems for their perceived advantages in dust control and flexible operations, particularly for very fine powders below 100 microns.

Table of Contents

-

High Throughput and Continuous Material Flow

- Throughput Capacity of Bucket Elevators Maximizes Feed Line Efficiency

- Continuous Bucket Elevator Applications Ensure Steady Material Flow

- Material Handling Capabilities Support High-Volume Feed Operations

- Case Study: Throughput Improvement in a Poultry Feed Plant Using Bucket Elevators

- Trend Toward Larger-Capacity Bucket Elevators in Modern Feed Mills

- Energy Efficiency Compared to Pneumatic Conveying Systems

-

Gentle Handling to Preserve Feed Quality

- Gentle Handling of Fragile Materials Preserves Pellet Integrity

- Bucket Styles and Discharge Methods Influence Material Degradation

- Data Point: 30% Reduction in Fines Generation With Centrifugal Discharge Bucket Elevators

- Controversy Analysis: Trade-offs Between Speed and Material Damage in Bucket Elevator Operation

- Space-Saving Vertical Conveying for Compact Mill Layouts

- Low Dust and Fines Generation Improve Safety and Product Quality

- FAQ