Raw Material Composition and Particle Size Optimization

Effect of Raw Material Composition and Particle Size on Mash Flow and Pellet Formation

Getting the right mix of particle sizes between 2 and 5 microns makes a big difference in how materials flow through pellet mill dies and keeps everything holding together properly. When particles drop below 2.5 microns, they actually create more friction inside the die, increasing resistance by about 18% because they pack too tightly. On the flip side, anything bigger than 8 microns tends to make pellets less dense, sometimes cutting density down around 30% according to recent industry reports from Feed Production Analysis last year. Research published in material sciences journals back in 2023 showed something interesting too: when feedstock has consistent particle sizes throughout, it boosts the Pellet Durability Index by roughly 23 points over those made from unevenly ground materials. This matters a lot for quality control in production settings.

Fiber Content in Feed and Its Impact on Pellet Quality and Die Throughput

High-fiber ingredients (>12% crude fiber) require 15–20% additional conditioning moisture to prevent die clogging. However, fiber’s natural binding properties enhance pellet durability by up to 14% when combined with starch-rich components. Exceeding 20% fiber inclusion reduces die throughput by 35% due to elevated frictional heat generation.

Inclusion of Coproducts and Their Effect on Pelleting Process Efficiency

Coproducts like distillers’ grains or wheat bran lower production costs but necessitate precise grinding adjustments. For every 10% coproduct inclusion, pellet mills require a 7% higher compression ratio to maintain pellet density. Blending oilseed meals with 8–10% coproducts optimizes lubrication without interfering with starch gelatinization.

Grinding and Particle Size Optimization for Improved Pellet Integrity

Achieving 80% particle uniformity (±0.5 mm) reduces fines by 42% and cuts energy use by 19%. A staggered grinding approach (coarse ‘ fine ‘ medium) enhances pellet integrity by 31% compared to single-pass methods (2024 particle engineering report). Target post-grind particle sizes of 600–800 µm for livestock feeds and below 500 µm for aquaculture formulations.

Conditioning: Temperature, Moisture, and Retention Time Control

Impact of Conditioning Temperature on Starch Gelatinization and Pellet Binding

Conditioning temperatures between 60–85°C promote starch gelatinization, where starches absorb moisture and form binding matrices essential for pellet strength. Below 50°C, starch remains ungelatinized, compromising cohesion. Above 90°C, protein degradation weakens pellet structure. Maize-based feeds achieve optimal binding at 75°C, balancing gelatinization efficiency with nutrient preservation.

Role of Moisture Addition and Steam Conditioning in Pre-Conditioning Phase

Steam conditioning adds 3–5% moisture to dry mash, softening fibers and enhancing plasticity for compression. Uniform steam distribution ensures even hydration—preventing brittle zones that lead to crumbling. In poultry feeds, precise moisture control improves pellet durability by 18% (FeedTech Journal 2023), while minimizing over-conditioning and associated energy waste.

Optimal Retention Time in Conditioner for Uniform Heat and Moisture Distribution

Keeping the mash in conditioners for around 30 to 60 seconds, whether they're laid out horizontally or standing vertically, gives enough time for heat and moisture to really get into the mix properly. When we cut this down too much, say below 25 seconds, the results aren't good at all. The mash just isn't conditioned properly and ends up making pellets that vary wildly in density from one batch to another. That's why many modern setups come equipped with those adjustable paddle mechanisms or variable speed controls. These features let operators tweak how long materials stay inside depending on what they're working with. Fat content matters a lot here, along with how big the particles actually are when they go in. Some facilities have found that adjusting these parameters can make all the difference between a successful run and having to scrap everything.

Balancing Moisture and Temperature Control to Prevent Die Clogging and Over-Drying

Excess moisture (>18%) causes slippage in pellet mill dies, accelerating wear and clogging. Conversely, under-conditioned mash (<10% moisture) increases friction, raising die temperatures to 100–120°C and risking scorching. Integrating real-time moisture sensors helps maintain balance—reducing die replacement costs by $740k/year in large-scale operations (2024 Feed Processing Report).

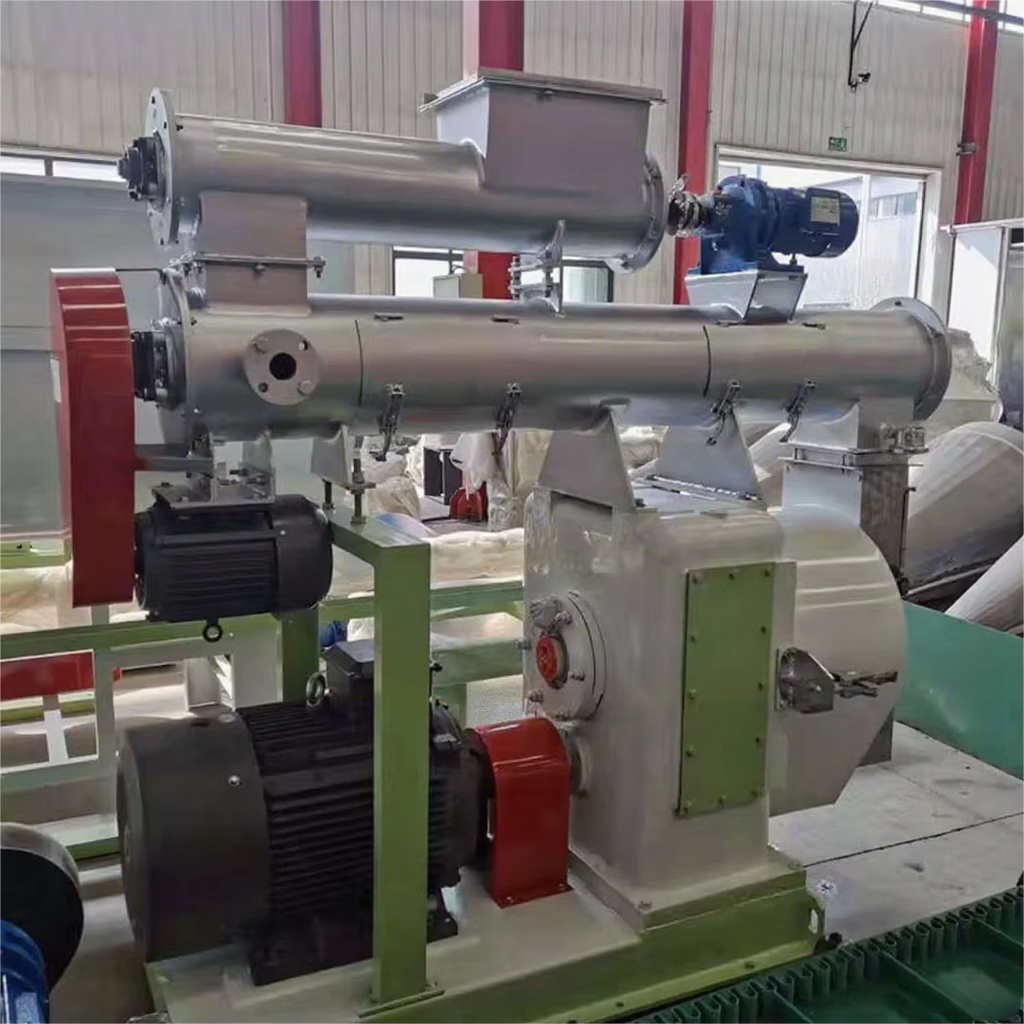

Pellet Die Design and Equipment Maintenance

Influence of Compression Ratio, Thickness, and Hole Diameter on Pellet Density and Output

Die geometry directly affects production efficiency. A 10:1 compression ratio is ideal for durable poultry feed pellets, while thinner dies (45–60 mm) with 4–6 mm holes suit high-output aquatic feeds. Excessive compression raises energy consumption by 18–22% (Feed Production Quarterly 2023) and may damage heat-sensitive additives like probiotics.

Wear and Maintenance of Pellet Mill Ring Die & Roller Affecting Pellet Consistency

Roller-die friction accounts for 73% of component wear during continuous operation. Following industry maintenance protocols—including biweekly groove depth checks and annual roller resurfacing—maintains pellet diameter consistency within ±0.5 mm. Dies worn beyond 0.3 mm depth cause up to 12% variation in pellet length, affecting packaging efficiency.

Die and Roll Maintenance Schedule to Ensure Long-Term Equipment Performance

A structured three-tier maintenance plan extends die life by 40–60%:

- Daily: Air blow-out of die holes at 4–6 bar pressure

- Weekly: Boroscope inspection of internal channels

- Quarterly: Full disassembly and ultrasonic cleaning

Monitoring roll-to-die clearance via amp draw trends (ideal range: 85–105A for 150kW mills) reduces unplanned downtime by 92% compared to reactive approaches.

Formulation, Additives, and Mixing Efficiency

Formulation Design and Nutritional Balance Influencing Pellet Bindability

Formulations with 18–22% protein and 3–5% starch exhibit optimal binding due to favorable molecular adhesion. Excess fiber (>8%) hinders compressibility, while insufficient structural carbohydrates weaken pellet integrity. Trials show soybean meal-based feeds achieve a 92% PDI, outperforming high-rye formulations (84% PDI).

Use of Additives and Binders to Enhance Physical Pellet Quality Parameters

Lignosulfonate binders (0.5–1.5% inclusion) improve water resistance by 35% and reduce fines during handling. Hydrocolloids like guar gum enhance mash plasticity, facilitating smoother extrusion. However, total additive levels above 3% risk nutrient dilution and cost inefficiencies without proportional quality gains.

Mixing Efficiency and Coefficient of Variation (CV%) as Predictors of Pellet Uniformity

Mixing systems achieving ≤10% CV% produce pellets with 8% greater dimensional consistency. Research indicates that 4-minute mixing cycles at 25 RPM reduce starch segregation by 18% compared to standard protocols.

Mash Moisture Content and Its Role in Determining Final Pellet Durability

Maintaining mash moisture between 15–18% before pelleting prevents brittle fractures. Each 1% deviation from this range lowers PDI by 6–8 points, with under-dried mixes (<14%) leading to irregular surfaces in finished pellets.

Cooling Process and Post-Pelleting Quality Assessment

Cooling & Drying Parameters: Airflow, Bed Depth, and Residence Time

When we control the cooling process properly, it helps reduce those pesky moisture differences inside the pellets, which keeps them intact overall. According to Techhexie from 2023, air moving at around 15 to 20 meters per second works best for transferring heat while keeping materials safe. Most counterflow cooler systems take somewhere between 8 and 12 minutes to get pellets stable at temperatures no more than 5 degrees Celsius above what's normal outside, plus moisture levels should stay below 13%. These are pretty important benchmarks because they stop mold growth and keep things stable during storage periods. Something else worth noting is bed depth issues cause about a quarter of all problems related to cooling. When beds aren't set right, they create these damp spots where airflow isn't consistent enough throughout the batch.

Preventing Cracks and Fines Through Optimized Cooling Process

Rapid surface cooling traps steam internally, causing cracks during handling. Gradual cooling (≤3°C per minute) reduces fines by 18–22% in high-capacity systems. Modern multi-zone cooling beds adjust air volume using real-time thermal imaging, cutting energy use by 5% versus conventional methods.

Pellet Durability Index (PDI) Measurement as a Standard Quality Benchmark

The pellet durability index (PDI) measures structural integrity via standardized tumbling tests. A ≥90% PDI is standard for poultry feeds; aquatic feeds require ≥95% due to prolonged water exposure. Mills using automated PDI sampling every 30 minutes reduce product returns by 12% compared to manual hourly testing.

| Parameter | Optimal Range | Quality Impact |

|---|---|---|

| Cooling Duration | 8-12 minutes | Prevents internal moisture >2% differential |

| Final Pellet Temp | Ambient +5°C max | Reduces surface cracking risk by 40% |

| PDI Testing Frequency | Every 30 minutes | Lowers out-of-spec batches by 15% |

Frequently Asked Questions

What is the ideal particle size for pellet formation?

Particle sizes between 2 and 5 microns are ideal for efficient material flow through pellet mill dies.

Why is fiber content important in feed formulation?

Fiber content influences pellet durability and die throughput, enhancing pellet quality when balanced properly with moisture and starch.

How does conditioning temperature affect pellet binding?

Conditioning temperatures between 60–85°C promote effective starch gelatinization and pellet cohesion.

What is the role of die geometry in pellet production?

Die geometry affects production efficiency, impacting compression ratios, energy consumption, and the suitability for various feed types.

Table of Contents

-

Raw Material Composition and Particle Size Optimization

- Effect of Raw Material Composition and Particle Size on Mash Flow and Pellet Formation

- Fiber Content in Feed and Its Impact on Pellet Quality and Die Throughput

- Inclusion of Coproducts and Their Effect on Pelleting Process Efficiency

- Grinding and Particle Size Optimization for Improved Pellet Integrity

-

Conditioning: Temperature, Moisture, and Retention Time Control

- Impact of Conditioning Temperature on Starch Gelatinization and Pellet Binding

- Role of Moisture Addition and Steam Conditioning in Pre-Conditioning Phase

- Optimal Retention Time in Conditioner for Uniform Heat and Moisture Distribution

- Balancing Moisture and Temperature Control to Prevent Die Clogging and Over-Drying

- Pellet Die Design and Equipment Maintenance

-

Formulation, Additives, and Mixing Efficiency

- Formulation Design and Nutritional Balance Influencing Pellet Bindability

- Use of Additives and Binders to Enhance Physical Pellet Quality Parameters

- Mixing Efficiency and Coefficient of Variation (CV%) as Predictors of Pellet Uniformity

- Mash Moisture Content and Its Role in Determining Final Pellet Durability

- Cooling Process and Post-Pelleting Quality Assessment

- Frequently Asked Questions