Key Factors Affecting Feed Grinder Efficiency for Corn and Soybeans

How Particle Size Reduction Impacts Feed Quality and Digestibility

The consistency of particle size really matters for how well livestock grow. Studies indicate that when corn and soybeans are ground between 600 and 800 microns, feed conversion rates can jump anywhere from 15 to 20 percent according to Springer's findings last year. When particles are too big, animals don't absorb nutrients as effectively. But going too small isn't good either since it raises energy expenses by around 18 to 22 percent and actually creates breathing problems for chickens and turkeys. Looking at data from 14 different feed mills back in 2023 showed something interesting: those who got their particle sizes just right saw waste drop by nearly a quarter and calves gained weight almost 9.5 percent faster than regular batches.

Energy Consumption in Grinding: Corn vs. Soybeans

Corn actually needs around 12 to 15 percent more energy per ton than soybeans because of how dense its endosperm is. The moisture content matters too - corn works best at 12-14%, whereas soybeans need less at 10-12%. Research published in Nature last year looked at this stuff closely. They found that when using 9mm screen holes instead of 14mm ones, corn grinding energy dropped by nearly a third. Soybeans didn't show such dramatic changes though, only about 8% difference in their tests. Interesting thing happens with hammer speed too. When operators push past 80 meters per second, corn processing gets 33% faster. But watch out for soybeans at those speeds since they start getting damaged from all that heat buildup.

Moisture Content, Hardness, and Other Crop-Specific Influences

| Factor | Corn Impact | Soybean Impact |

|---|---|---|

| Moisture >15% | 20% energy increase | 12% energy increase |

| Kernel hardness | Requires 30% more torque | Brittle hulls allow lower RPM settings |

| Grind temperature | Exceeding 65°C degrades starch | Tolerates up to 75°C without protein denaturing |

Field trials show a 3% reduction in corn moisture decreases grinding costs by $1.72/ton while maintaining pellet integrity (Tandfonline, 2022). Soybean’s lower silica content (0.2% vs. corn’s 1.4%) extends hammer mill screen life by 400–600 operating hours.

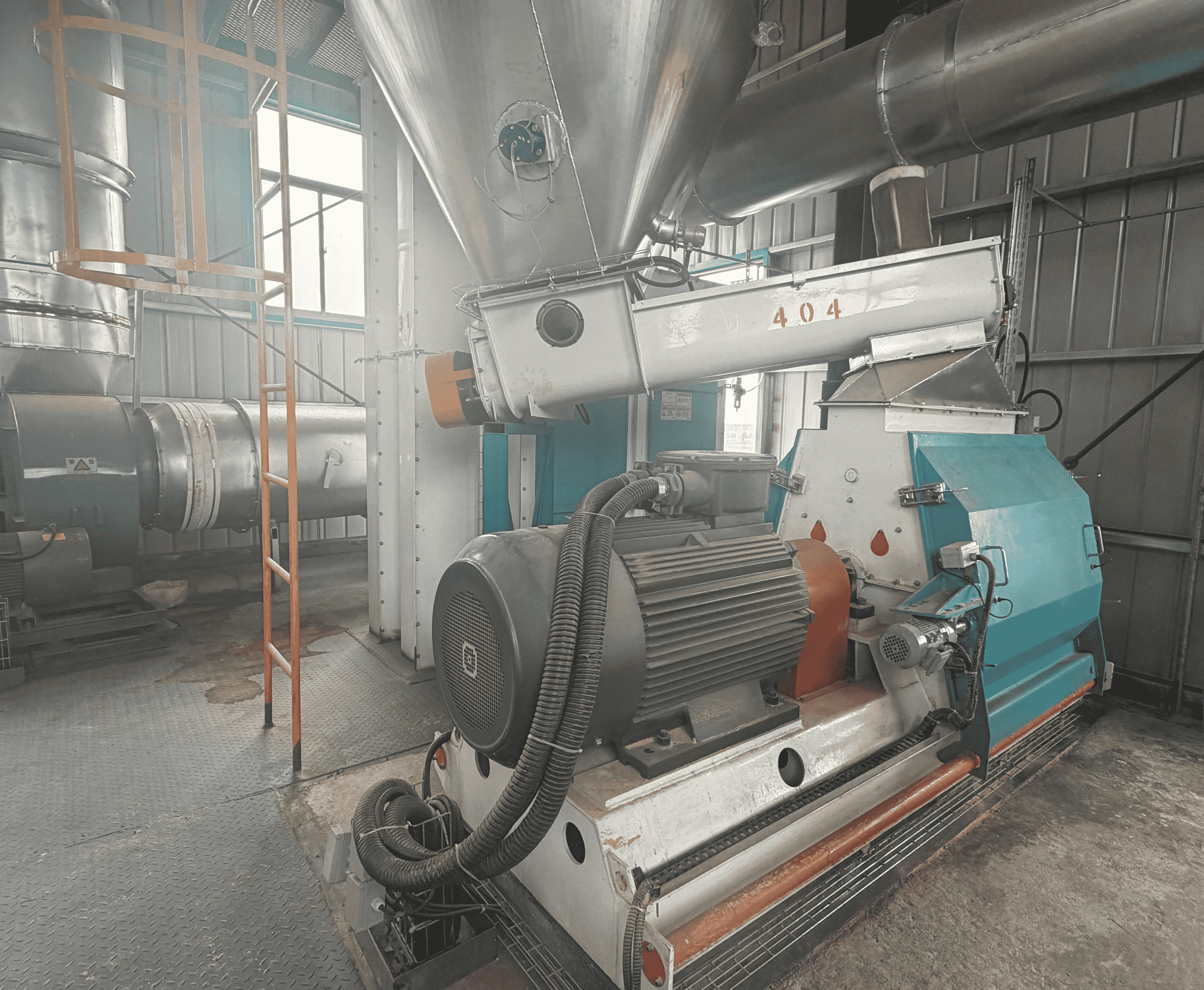

Hammer Mill Performance for Corn and Soybean Processing

Grinding Efficiency of Hammer Mills on Maize and Soybean Meal

Hammer mills work best when the screen holes, rotor speed, and how fast material gets fed into them match what kind of crop is being processed. When grinding corn, most operators find that screens between 3 to 6 millimeters combined with rotor speeds around 1,800 to 2,100 revolutions per minute produces particles averaging about 600 to 800 micrometers in size. This setup keeps energy consumption under 30 kilowatt hours per ton according to recent studies from Springer in 2025. For soybeans though, things need to be much finer. Screens measuring just 2 to 3 mm at lower speeds of 1,400 to 1,600 rpm seem to work well for getting good protein digestion without creating too much heat during processing. Some research indicates that if corn gets ground down below 500 micrometers, the amount processed actually goes down by about 17%. And interestingly enough, reducing soybean particles to similar sizes takes roughly 22% more power than doing the same with corn.

Screen Size Selection and Its Effect on Particle Size Distribution

Screen hole diameter controls particle uniformity—a key determinant of feed quality. Data from 12 agricultural trials reveal:

| Crop | Optimal Screen (mm) | Avg. Particle Size (µm) | Energy Use (kWh/ton) |

|---|---|---|---|

| Corn | 4.5–5.5 | 720–880 | 24–28 |

| Soybean | 2.5–3.5 | 480–550 | 32–36 |

Smaller screens (≤3 mm) improve consistency but raise energy costs by 18–25%. For mixed operations, dual-screen setups effectively balance nutritional needs and operational efficiency (Springer 2025).

Balancing Production Rate and Energy Use in Hammer Mill Operations

Hammer mills designed for high throughput can handle around 8 to 12 tons of corn per hour, though they typically use about 40% more energy than their precision counterparts. Efficiency peaks when the motor runs between 85% and 90% capacity. If the mill operates below this range, roughly 12-15% of energy gets wasted. Going over this sweet spot raises maintenance expenses by approximately 18 cents per ton processed. Thanks to modern variable frequency drives, operators now have the ability to make on the fly adjustments. These systems cut down on wasted power, saving about 9% during corn processing and an impressive 14% when working with soybeans according to research from Academia.edu back in 2015.

Roller Mill vs. Hammermill: Comparing Efficiency for Corn and Soybeans

Corn Grinding: Roller Mill Precision vs. Hammermill Throughput

When it comes to grinding corn, roller mills produce much better particle uniformity than hammer mills do. Most roller mill setups hit around 85 to 90 percent consistency, while hammer mills typically manage only 60 to 75 percent. The way roller mills work actually cuts down on starch damage by somewhere between 12 and 18 percent, which makes the feed easier for animals to digest according to a study published in Nature last year. Hammer mills might process anywhere from 8 to 12 tons every hour, making them good choices when production volume is the main concern. But there's a catch. Those same hammer mills tend to create uneven particle sizes that can lower digestibility rates by about 5 to 7 percent in poultry operations. On the plus side, roller mills generally use 30 to 40 percent less energy per ton of grain processed. However, operators need to keep checking and adjusting the gaps regularly if they want their equipment to continue performing at optimal levels.

Soybean Processing Performance: Which Feed Grinder Wins?

The fibrous hulls and high oil content of soybeans create some real processing headaches for farmers and feed manufacturers alike. When it comes to grinding soybean meal, hammer mills generally do better than their roller mill counterparts. Most hammer mills can get around 92 to 95 percent of the material through 3 mm screens, while roller mills typically manage only 80 to 85 percent. But there's a catch. Studies looking at how fast these machines run show hammer mills actually eat up more power. At tip speeds around 28 meters per second, they're consuming somewhere between 22 and 28 kilowatt hours per ton of soybeans processed. That works out to be about 35 percent higher energy consumption compared to roller mills. For making textured feeds where some hull remains important, roller mills have their advantages too. They tend to keep roughly 15 to 20 percent more of those fibrous materials intact, which makes a difference in maintaining proper rumen function for dairy cows grazing on this type of feed.

Energy Efficiency and Long-Term Operational Costs Compared

According to a study from 2023, roller mills can actually save around seven thousand four hundred to nine thousand two hundred dollars annually on energy costs when looking at a facility processing ten thousand tons. Hammer mills do come with about thirty percent less upfront investment though there's a catch. The parts that wear out fast like hammers and screens tend to break down three to four times more frequently than what we see with roller mills. This means operators end up spending somewhere between one dollar twenty and one dollar fifty extra per ton over time just replacing these components. Some facilities are now adopting hybrid approaches where they first crack materials using roller mills then finish up with hammer mills for the final grind. This mixed strategy not only cuts overall energy consumption by roughly twenty five to thirty percent but also extends the life of those hammer mill parts almost twice as long as they would normally last.

Choosing the Right Feed Grinder Based on Your Production Goals

When to Choose a Hammermill: High Throughput and Flexibility

For farms and processing plants where speed matters most, hammermills really shine when dealing with crops like corn and soybeans. The bigger industrial versions can crank out around 20 tons an hour, which makes sense for those running full scale operations day after day. What sets these machines apart is their adjustable screen system that lets workers tweak how fine or coarse the grind ends up being somewhere between 400 to 1,200 microns. This matters because different animals need different textures in their feed while still keeping production moving at good pace. Hammermills handle mixed loads particularly well too, something many other systems struggle with. Plus, switching from one grain type to another happens pretty fast compared to alternatives, which comes in handy during harvest seasons or when market conditions change suddenly. While they do cost more to run than some simpler options, most operators find that extra expense worth it given all the versatility these machines offer in ever changing agricultural settings.

When a Roller Mill Is the Better Investment: Consistency and Energy Savings

When it comes to operations where precision matters most, roller mills tend to be the go-to option. These machines produce really consistent particle sizes with about a 5% variation range, something that's absolutely critical for making good quality poultry and swine feed. Compared to hammermills, roller mills actually save between 15 and 30% in energy costs per ton when working with corn. Why? Because they use compression grinding rather than all that repeated impact stuff that wastes so much energy. And things get even better when dealing with soybeans since these require far less mechanical force overall. Sure, the initial investment runs about 20 to 40% higher than hammermills, but think about the long run. Roller mill parts last anywhere from 3 to 5 years compared to just 12 to 18 months for hammermill screens. Plus there's that ongoing energy savings factor. For anyone running a feed operation that needs both cost control and consistent quality over time, especially folks who make premixes or handle medicated feeds where consistency is non-negotiable, roller mills definitely pay off in the end.

FAQ Section

What is the optimal particle size for grinding corn and soybeans?

Studies indicate the ideal particle size for grinding corn and soybeans ranges between 600 and 800 microns to improve feed conversion rates and nutrient absorption.

How does screen size affect grinding efficiency?

Screen size directly influences particle uniformity and energy consumption. Smaller screens improve consistency but increase energy usage.

What are the key differences between hammer mills and roller mills?

Hammer mills excel in high throughput and flexibility, while roller mills offer better particle consistency and energy savings, especially important for operations requiring precision.

How can moisture content and kernel hardness influence grinding?

Higher moisture content increases energy needs, while kernel hardness requires more torque for corn processing compared to soybeans' brittle hulls, allowing for lower RPM settings.