Why Noise Reduction Matters in Feed Grinder Selection

OSHA compliance, operator hearing safety, and livestock stress reduction

The loud noises coming from feed grinders present serious problems for both health and compliance that need addressing before they become major issues. The Occupational Safety and Health Administration requires workers who are regularly exposed to sounds over 85 decibels to wear hearing protection. Many older grinding machines actually produce noise well beyond this limit. When people work around these machines day after day without proper ear protection, they risk losing their hearing permanently. Farmers report that agricultural workers suffer about three times more hearing loss compared to those working in other industries according to NIOSH data from last year. Animals also get stressed out by all the noise. Dairy farmers have noticed cows showing signs of stress when the grinding starts up, with cortisol levels spiking by as much as 25%. This stress translates into lower weight gains and reduced milk production. Cutting down on noise isn't just about following rules anymore it's becoming essential for maintaining animal welfare while keeping operations productive.

The hidden cost of noise: Downtime, communication barriers, and farm community relations

The constant noise from feed grinders causes all sorts of problems that get ignored when buying new equipment. When operators can't hear each other properly during grinding operations, mistakes happen more often and safety becomes a bigger concern. Plus, those required noise checks always seem to come at inconvenient times, shutting down operations unexpectedly. For farms located close to neighborhoods, noise complaints are becoming a major headache. According to AgriSafety Journal research from 2022, nearly seven out of ten such farms experience conflicts with neighbors about equipment noise within just five years of starting up. These disputes often result in strict local regulations or forced operating hours. What many don't realize is how vibrations from under-dampened grinders actually wear out parts faster. Bearings and motors degrade quicker this way, which means repair bills go up anywhere between 15% to 30% over ten years. Looking at these added costs makes it clear that controlling noise isn't just about following rules anymore. It's really about keeping farm operations viable long term while getting along with surrounding communities.

Key Noise Reduction Technologies in Modern Feed Grinders

Sound-dampening enclosures and acoustic liner materials

Manufacturers these days are starting to use special acoustic treatments aimed right at those pesky mechanical noise spots. They often put engineered polymer stuff along with damping materials inside grinding chambers and around gears so vibrations get absorbed before turning into annoying sounds. Tests published in academic journals indicate these methods cut down noise levels by about 8 to 12 decibels when compared to regular equipment without such lining. When picking materials, companies have to find that sweet spot between lasting power and how well they control sound. Micro-perforated panels work great when combined with mineral wool cores for absorbing high frequency noises. This matters a lot because most grinding machines create a lot of sharp, sudden sounds that need proper handling if we want quieter workplaces overall.

Vibration isolation mounts and dynamic balancing systems

The way vibrations travel through machinery plays a big role in creating unwanted noise pollution. Modern feed grinders have several ways to tackle this problem. They use rubber-like pads between the motor and frame to stop vibrations from spreading. The rotors are balanced using computers so they stay within about 0.05 mm per kilogram of imbalance. Special dampers also help by targeting particular frequencies that cause annoying resonance effects. All these different approaches work together to stop vibrations from getting worse as they move through the structure. When this happens, people actually hear the noise increase by around 5 to 10 decibels, which makes a real difference in environments where machines are running at full speed or under heavy loads. Noise control becomes especially important in these situations because workers need protection from excessive sound levels.

Integrated dust suppression and its indirect noise-dampening effect

Mist based dust suppression systems mainly target airborne particles but they also offer some pretty good acoustic benefits. When water droplets get into the air, they actually help absorb sound. The air becomes heavier when it's moist, which makes high frequency noises not travel as far. Field reports show that these systems can cut down background noise by around 3 to 7 decibels during grinding tasks where moisture control matters most. What we're seeing here is a nice bonus effect that cuts down on overall noise levels while making the air cleaner and safer to work in. For companies running feeding equipment today, this kind of dual purpose solution just makes sense from both practical and safety standpoints.

Comparing Noise Performance Across Feed Grinder Types

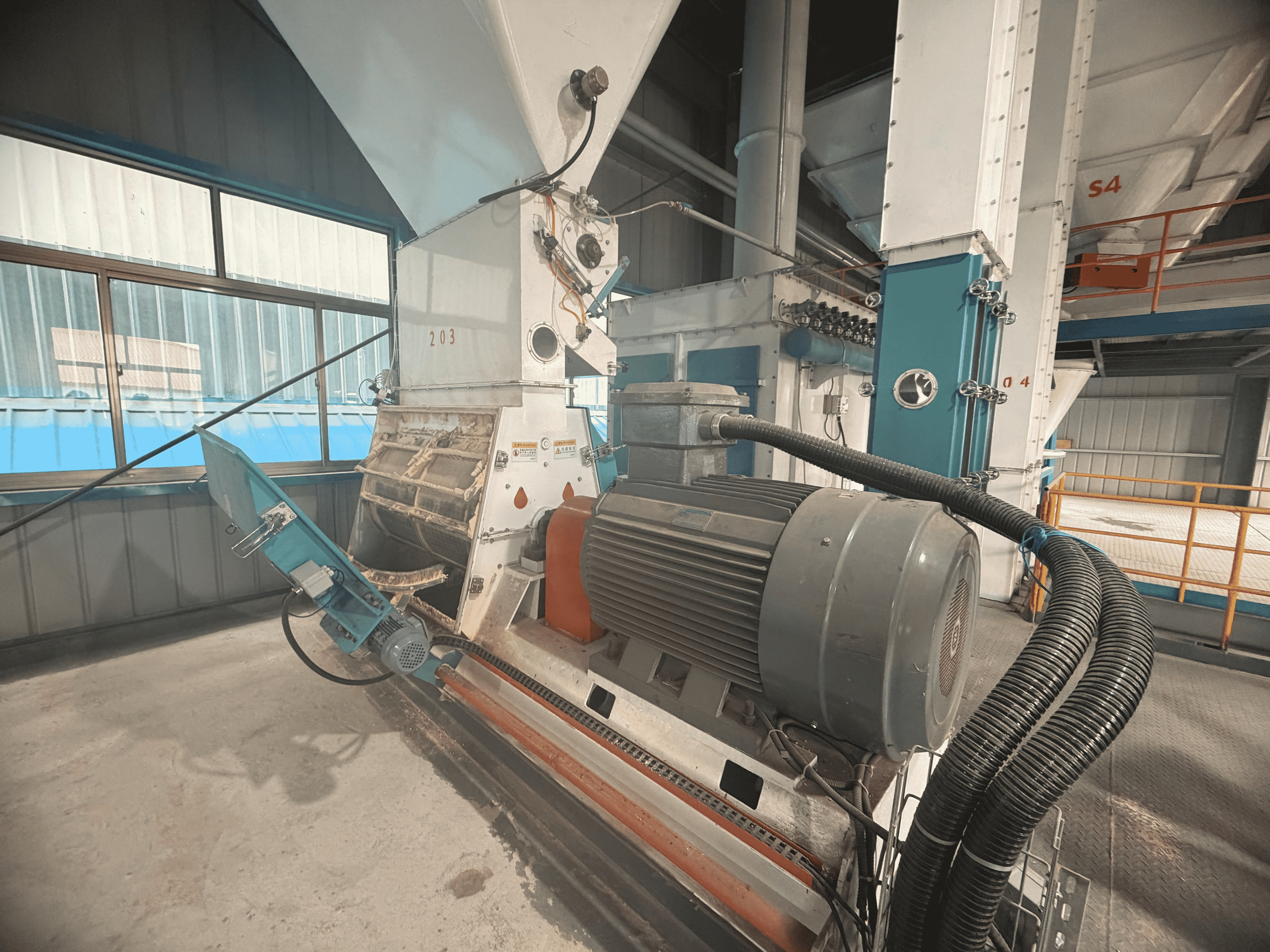

Hammer mills (85–95 dB): Trade-offs between throughput and noise control

Hammer mills can process large volumes of material, but they come with some serious noise issues. These machines typically run around 85 to 95 decibels, which is basically like standing next to a busy highway full of trucks. When workers are exposed to sounds this loud for eight hours straight, OSHA regulations mandate hearing protection equipment. And let's be honest, anyone who spends too much time near these machines without proper gear risks permanent hearing loss. The reason behind all this noise? Those spinning rotors inside go absolutely wild at speeds between 1,800 and 3,600 revolutions per minute, creating massive amounts of sound as materials smash against each other. Industrial grade hammer mills might handle anywhere from 10 to 30 tons per hour, but nobody enjoys trying to talk over the constant roar or deal with stressed animals in nearby pens. Some companies install soundproofing solutions, but those upgrades usually cut down on processing power by about 15 to 20 percent. So plant managers find themselves stuck between wanting maximum output and needing to keep noise levels within safe limits.

Roller mills (72-80 dB) and knife cutters (76-83 dB): Quieter alternatives for low-throughput or sensitive environments

Roller mills compress feed through counter-rotating cylinders, generating 72–80 dB—comparable to a vacuum cleaner. Their gradual crushing mechanism avoids explosive particle impacts, reducing noise at the source. Similarly, knife cutters operate at 76–83 dB using shearing forces rather than percussion . Both suit:

- Dairy/equine facilities, where stressed animals exhibit 18% lower yield in noisy environments

- Residential-adjacent farms, needing to comply with local noise ordinances (typically â Â75 dB at property lines)

-

Small-scale operations, processing under 5 tons/hour

Though quieter, these feed grinders sacrifice throughput: roller mills handle fibrous materials poorly, while knife cutters require frequent blade maintenance. For context, every 10 dB reduction represents a halving of perceived loudness to human ears.

How to Verify and Compare Real-World Noise Data for Feed Grinders

Reading certified sound pressure level (SPL) reports: Distance, load, and measurement standards

Getting accurate noise measurements means following standard tests according to ISO 3744 guidelines. These standards set out where exactly to measure sound levels around equipment, usually somewhere between 1 and 7 meters away, while the machinery runs at full capacity. Good quality manufacturers will make available their Sound Pressure Level reports that show all these details because they matter a lot for proper assessment. A recent study in agricultural acoustics back in 2024 revealed something interesting: almost seven out of ten pieces of equipment had differences ranging from 3 to 8 decibels depending on whether measurements were taken at one meter or seven meters distance. When looking at manufacturer reports, always check if they clearly mention these important parameters.

- Testing methodology compliance (ISO 3744 or ANSI S12.5)

- Operational load during measurements (e.g., 100% capacity)

- Background noise calibration to eliminate interference

Red flags in marketing claims vs. third-party test data

Be skeptical of generic statements like âlow-noise operationâ without certified documentation. Legitimate SPL reports always specify testing conditions and carry timestamps from accredited laboratories. Warning signs include:

- Claims outperforming physical limitations (e.g., sub-70 dB hammer mills contradict acoustic physics)

- Missing load condition specifications

- Brand-supplied data without independent verification

The 2023 Farm Equipment Audit revealed manufacturer-supplied noise data averaged 9% lower than third-party tests. Prioritize feed grinders with OSHA-compliant certification from independent acoustics labs for genuine performance validation.

A Practical 5-Step Framework to Select Your Low-Noise Feed Grinder

Setting up a proper selection method helps find a feed grinder that works well for daily operations while keeping noise levels down. Start by figuring out what noise levels are acceptable at the facility. Look at OSHA guidelines which set 85 decibels as safe for eight hours straight, plus check studies about how animals react to loud noises – most get stressed when sounds go over around 70 dB. Next, pick the right type of grinder depending on how much material needs processing each day. Hammer mills work best for big operations but need special enclosures to muffle the noise. Roller mills handle medium amounts and fit better in areas where quiet is important. Knife cutters are good for smaller batches though they aren't used as widely. Before buying, double check those sound level numbers manufacturers provide. Get hold of independent testing reports following ISO 3744 standards and pay attention to details like where measurements were taken and what kind of load was used during testing. Actually test different models on site too. Use proper equipment to measure noise levels where workers stand and near animal pens. Lastly, think about how easy it will be to maintain things like acoustic liners and vibration dampers after installation. Sometimes these noise reduction features can actually slow things down if not properly integrated into regular maintenance routines. Taking all these steps together creates a balance between getting work done efficiently and meeting both legal requirements and ethical considerations regarding animal comfort.

FAQ Section

- Why is noise reduction important in feed grinder selection? Noise reduction is crucial as it ensures OSHA compliance, protects operator hearing, reduces livestock stress, and aids in maintaining good relations with surrounding communities.

- What technologies are used to reduce noise in feed grinders? Key technologies include sound-dampening enclosures, acoustic liner materials, vibration isolation mounts, dynamic balancing systems, and integrated dust suppression systems.

- How do different types of feed grinders compare in terms of noise? Hammer mills are typically loud (85-95 dB), while roller mills (72-80 dB) and knife cutters (76-83 dB) provide quieter alternatives but often with lower throughput.

- What should be considered when verifying noise data from manufacturers? Ensure sound measurements comply with standards like ISO 3744, consider the operational load during tests, check for independent verification, and watch out for overly ambitious claims that contradict acoustic physics.